|

|

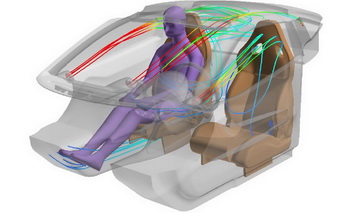

Ferrari is using software from ANSYS, which

develops simulation software and technologies

designed to optimise product development

processes, to predict thermal comfort in the

vehicle's interior. |

|

|

|

|

|

Maranello sports car maker

Ferrari is using software from ANSYS, which

develops simulation software and technologies

designed to optimise product development

processes, to predict thermal comfort in the

vehicle's interior.

Automobile

thermal comfort is important to prospective buyers, and, for

this reason, Ferrari has made this a high priority in

vehicle design. In order to assess comfort not only

qualitatively but also quantitatively, Ferrari worked

together with the University of Pisa in Italy to define

thermal comfort indices and to make comprehensive

evaluations of the general aspects of thermal comfort.

Because an experimental approach was not practical, the

investigating engineering team used fluid dynamics software

from ANSYS to perform the calculations.

"Thermal comfort

is an individual perception and not a measurable value,"

explained Giovanni Lombardi, professor of airplane

aerodynamics and vehicle aerodynamics at the University of

Pisa. "Qualitative statements from a test team do not really

help car developers who want to measure the design quality

and usefulness of design changes objectively and comparably.

An experimental approach for determining the data required

was virtually impossible. For that reason, we used

engineering simulation software from ANSYS, which had

advantages for this scenario and rendered accurate and

reliable results."

The research

team based its resulting "global thermal comfort index" on

several local indices: the thermal equilibrium of the human

body, discomfort caused by drafts, and horizontal and

vertical temperature gradients. A number of factors were

studied, including the car's velocity and materials

(leather, glass, aluminium) as well as sensitivity to

warming or cooling on various body sites (leg, arm, face,

covered with clothing or not), solar irradiance, vehicle

interior size, and air flow.

"Ferrari and the

University of Pisa faced the difficult task of developing a

measure for quality. They saw a high business value in

applying our software and made profitable use of it," said

Jim Cashman, president and CEO of ANSYS, Inc. "The advantage

of Simulation Driven Product Development is that no complex

physical models or testing configurations are required, and

the design can be tested, optimised and, if necessary,

modified virtually at an early stage in the development

process. Companies across the whole industry spectrum -- not

just automotive -- are seeing the benefits of this process.

In this case, with help from ANSYS software, Ferrari is

living up to its expectations of designing one of the most

desirable brands worldwide."

|