|

|

The three year research and development

partnership between Fiat Automóveis,

Brazilian hydro-electric company Itaipu

Binacional and battery manufacturer KWO

which started with an electric-powered Palio

pilot project is now expanding into the

production of a fleet of similarly

zero-emission producing Palio Weekend cars. |

|

|

|

|

|

The

three year research and development partnership

between Brazilian hydro-electric company Itaipu

Binacional, Fiat Automóveis, and Swiss

hydro-electric company Kraftewerke Oberhasli (KWO)

which started with an all-electric-powered Palio

pilot project is now expanding another step with

the production of a fleet of similarly

zero-emission producing Palio Weekend Elétrico

cars.

This

ambitious project got underway in 2006 with the

aim of production a zero-emission vehicle that

also emitted virtually no noise, and developing

the ability to manufacture and commercialise

such a vehicle in Brazil and thus increase the

options in the area of mobility for the

Brazilian consumer. Fiat Automóveis has always

been at the forefront of technological

pioneering and the Brazilian arm of the Fiat

Group was the first to introduce an

alcohol-powered car as well as more recently

becoming the first to commercialise a car that

can run on no less than four different fuel

sources (the Tetrafuel system). The project with

the Itaipu, the state-owned company which

operates the huge hydro-electric dam on the

Brazil-Paraguay border that provides much of

Brazil's electricity, and Swiss fim KWO, got

kicked off with the production of a trial fleet

of Palio Elétrico models that run on electric

motors and have been used in a successful pilot

trial by Itaipu. The Palio Elétrico is fitted

with an efficient electric motor, a battery pack

located in the boot, produces zero-emissions,

and the only noise it emits is the contact the

tyres make with the road surface.

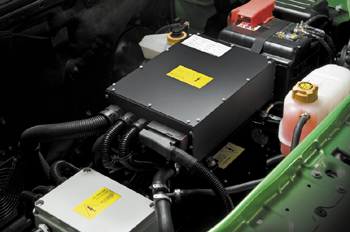

The

next phase of the project is seeing the

production of a fleet of Palio Weekend Elétrico

vehicles. The base car with all unnecessary

components (such as engine, gearbox, water

cooling system, fuel tank, etc) is shipped from

the Fiat Automóveis factory at Betim in the

Minas Gerais region of Brazil, to the giant

Itaipu hydro-electric plant (the largest in the

world) where it is converted in a dedicated unit

on a special production line where it receives

its new electric motor, transmission system and

batteries. The new powerplant delivers standard

power of 15 Kw (20 CV) or maximum useable power

of 28 Kw (37.8 CV) while its normal torque is 50

Nm (5.1 kgm) and maximum torque is 124 Nm (12.6 kgm), all of which allows the Palio Weekend

Elétrico to whizz itself from standstill to 60

km/h in 9 seconds and reach a maximum speed of

100 km/h.

The

compact nature of the new electric motor and

transmission, despite the additional weight of

the bulky new battery pack, allows a 41.5 kg

saving in the estate car's overall weight (1185

kg, along with a useful load carrying ability of

310 kg) compared to the production Palio

Weekend. The 253 V/19.3 Kwh nickel battery pack

allows the Palio Weekend Elétrico to achieve a

range of 120 km and it can be full recharged in

8 hours using any standard (220 V) domestic

power point. The batteries are also fully

recyclable as sustainability has been another

key objective of the project.

Externally the Palio Weekend Elétrico is

identical to its mass-production sister (the

charging socket is located behind the bodyside

flap that usually houses the conventional fuel

filler pipe), however inside there are several

immediately-noticeable visual changes. In place

of the manual gearstick comes a new 3-position

stick (drive, neutral or reverse) while a new

digital LCD display on the centre of the

dashboard informs the driver of the battery's

load, tension, life and temperature, and a new

instrument cluster behind the steering wheel

eliminates the redundant gauges from the fuel

version to just record the speed. Also for

greater safety and security of the occupants the

suspension and brakes (257 mm diameter discs at

the front and 228 mm at the rear) have been

recalibrated.

Currently twenty one Palio Weekend Elétrico

vehicles have been built with the target being

to produce fifty by the end of the first quarter

of 2010. This experimental fleet will then be

used in extensive trials by the partners in the

project: Itaipu Binacional, KWO, AMPLA, CPFL,

Copel and Eletrobrás, as the reality of

commercialising a mass-produced electric car in

Brazil edges yet another step closer.

|