|

|

The Superquadro engine, so called because of

its over-square bore and stroke ratio, has

increased power to an absolute production twin-cylinder

milestone of 195hp and torque to 98.1 lb-ft (13.5kgm)

with user-friendly riding modes that deliver that power

appropriate to the rider’s style and

environment. |

|

|

|

With

just a matter of weeks to go until the final unveiling

of Ducati’s brand new 1199 Panigale at the EICMA

International Motorcycle Show in Milan (10-13 November),

the Italian manufacturer now reveals the secrets behind

the new Superquadro engine which will power the 2012

Superbike.

Ducati engineers were given a design

brief to create the new generation Superbike engine for

the Ducati 1199 Panigale: Increase power, torque and

user-friendliness and reduce overall vehicle weight and

scheduled maintenance costs.

The Superquadro engine, so called because of

its over-square bore and stroke ratio, has

increased power to an absolute production twin-cylinder

milestone of 195hp and torque to 98.1 lb-ft (13.5kgm)

with user-friendly riding modes that deliver that power

appropriate to the rider’s style and environment. Its

construction has enabled a reduction in overall

vehicle weight while major

services have been extended to 24,000km (15,000 miles).

Only Fabio Taglioni’s 90° L-twin

configuration and Desmodromic valve control have been

retained from previous engines. Everything else is new.

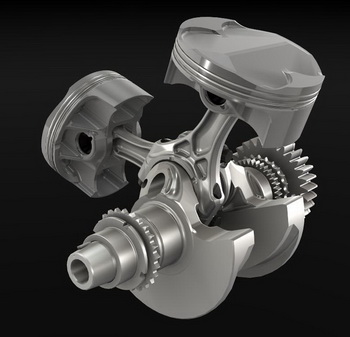

Engine architecture

With the engine designed to be a fully stressed member

of the chassis, its architecture has been completely

re-calculated to provide the best possible vehicle

construction for layout, weight distribution and

strength. The cylinders, which remain at 90° to each

other, have been rotated backwards around the crankcases

by a further 6°, until the front cylinder is 21° from

horizontal. This has enabled the engine to be positioned

32mm further forwards for improved front / rear weight

distribution in addition to perfectly positioning the

cylinder head attachment points for the 1199 Panigale’s

monocoque frame.

The crankcases, which are vacuum die-cast using Vacural®

technology to ensure optimal weight saving, consistent

wall thickness and increased strength, also incorporate

in their form the outer water-jacket of the “cylinder”,

eliminating the jointing face that used to exist at the

base of the cylinders. Instead, the Superquadro has

separate nikasil-coated aluminium “wet-liners” inserted

into the tops of the crankcase apertures. This design

enables secure fixing of the cylinder head directly to

the crankcase, improved sealing and enhanced heat

dissipation from the thin cylinder-liners directly into

the surrounding coolant.

The primary-drive casing, clutch casing and outer cover,

sump and cam covers are all cast in magnesium alloy,

ensuring a lightweight engine despite its increased

strength as an integral part of the chassis.

In addition to cylinder position, the crankcases now use

shell main bearings for the crankshaft, previously only

used by Ducati on the Desmosedici RR engine. Removing

the roller bearings has enabled an increase in diameter

of the crank journals for enhanced rigidity and an

increase the crankcase section around the main bearing

area for improved strength in line with the

Superquadro’s extreme power output. The shell bearings

are force-fed oil from internal drillings within the

main bearing pillars to keep the new crankshaft well

lubricated and is quickly scavenged back into the sump

with the introduction of a new Ducati feature, a highly

efficient MotoGP-style vacuum pump.

The pump is driven by the main oil pump shaft and

effectively maintains constant vacuum in the crankcase

area below the pistons, reducing atmospheric resistance

during the down-stroke of the piston and controlling the

internal “breathing” of the engine.

Dimensions

In calculating the optimum configuration to achieve the

next big step forward in power output for the L-twin

engine, Ducati and Ducati Corse engineers increased

engine speed and enhanced breathability with the

incredible bore and stroke of 112mm x 60.8mm. The

intense study of power and ridability resulted in an

output of 195hp @ 10,750rpm and 98.1 lb-ft (13.5kgm) @

9,000rpm. The new bore and stroke ratio of 1.84:1

effectively increases rpm with the ultra-short stroke of

the crankshaft and increases the cylinder area to enable

increased valves diameters. Inlet valves have increased

from 43.5 to 46.8mm and exhaust valves from 34.5 to

38.2mm.With such large inlet

valves operating at higher rpm, the intense inertial

forces have been controlled by using titanium instead of

steel, a solution only previously used on full “R”

models. The new valves are actuated by racing-derived

rocker arms, 'super-finished' for reduced friction and

fatigue and then coated in polymeric-like carbon (PLC),

a process originally developed for the aerospace

industry.

The race-derived Superquadro pistons have a distinctive

double-ribbed undercrown to achieve high strength and

reduced friction by using minimal piston wall surface

area. Using technology developed by Ducati Corse, the

design enables reliable operation of the 112mm diameter

pistons when performing at high rpm.

The improved volumetric efficiency of the increased

inlet valve diameters is further capitalised on by

increasing the oval throttle body dimensions from an

equivalent diameter of 63.9 to a massive and

high-flowing 67.5mm. The Ride-by-Wire throttle bodies

feed air across twin injectors per cylinder, one

positioned below the butterfly for enhanced flexibility

and one above for outright power.

Clean power

With such enhanced “breathing”, the challenge for the

Superquadro’s Design Engineers was to program

performance-optimised fuel mapping for a smoother

cycle-to-cycle engine operation, without compromising

emissions. To achieve this, Ducati introduced a

secondary air system that completes the oxidisation of

unburned hydrocarbons and effectively reduces HC and CO

levels. The system is activated when the engine ECU

recognises specific conditions in the engine’s operation

via the lambda and throttle opening sensors. It then

opens a valve enabling a flow of clean air from the main

airbox to a reed valve situated in each cylinder head,

which enables one-way flow into an air gallery exiting

into the exhaust port close to the exhaust valve.

Entering the hottest point of the exhaust gasses, the

fresh charge of air enhances the burn environment,

eliminating any unburned fuel that escapes during the

exhaust cycle under certain conditions.

Desmo dependent

With such an extreme engine, never before has Ducati's

unique Desmodromic system been so vitally important.

With the high engine speeds at which the Superquadro

operates combined with such large valves, it would be

impossible for the valve’s rocker-arm to follow the

steep closure profile of the cam lobe using normal valve

closure springs. The Desmo system actuates valve closure

mechanically with the same method and accuracy as it

opens, enabling steep cam profiles, radical cam timings,

large valves and high operating speeds. This system is

used on every single Ducati motorcycle and is constantly

proven on Ducati Corse’s World Superbikes and

Desmosedici MotoGP bikes.

The power of precision

Controlling such large valves with the precise

Desmodromic system also led engineers to replace the

original belt-drive concept, used since the introduction

of the Ducati Pantah in 1979, with a combined chain and

gear-drive arrangement. The conventional bush-type chain

runs from the crankshaft to the cylinder head where a

single sprocket positioned between inlet and exhaust

camshafts, is attached back-to-back to a gear wheel

mounted on its own short, dedicated shaft. The attached

gear meshes directly with gears on the ends of both the

inlet and exhaust camshafts, which are also designed

with +/- position adjustment for ultra-precise

cam-calibration. The cam chain, therefore, provides

highly efficient point-to-point drive route and,

tensioned automatically, provides continuous reliability

and further reducing the cost of routine maintenance.

On the end of each exhaust cam drive gear is a

centrifugal flyweight which retracts at speeds below

tick-over to rotate a “protrusion” from the concentric

section of the cam, thus creating sufficient inlet valve

lift to act as a de-compressor. This ingenious device

enables the Superquadro engine to be started easily

without using a larger battery and starter motor, which

has reduced overall vehicle weight by approximately

3.3kg (7.3lb). When the engine starts and the camshafts

begin to rotate at tick-over speed, the centrifugal

flyweight flicks out, retracting the “protrusion” back

into the cam and allowing complete valve closure for

full compression. This innovative feature further

underlines the lengths to which designers and engineers

have worked together in the single-minded pursuit of

weight-saving.

New transmission

Ducati’s engineers also capitalised on the opportunity

of the “blank canvas” project to increase dimension

between the centres of the six-speed gearbox shafts,

enabling larger diameter, stronger gears to transmit the

enhanced power output. New for a top-of-the-range Ducati

Superbike is a “wet”, oil-bath clutch. Based very

closely on the design of the Multistrada and Diavel

components, the clutch assembly features a “slipper”

function and a progressive self-servo mechanism that

compresses the friction plates when under drive from the

engine. While enhancing frictional efficiency, this also

results in a rider-friendly light clutch lever “feel” at

the handlebar. Conversely, when the drive force is

reversed (over-run), the mechanism reduces pressure on

the friction plates, enabling a true racing “slipper”

action, reducing the destabilizing effect of the

rear-end under aggressive down-shifting and provide a

much smoother feeling when closing the throttle or

down-shifting under normal riding conditions.

Performance perfection

Competition is the platform on which Ducati has always

challenged and measured itself. It is a discipline for

designers and engineers and the bedrock of motivation

for a company in which the constant desire for victory

has become a way of life. The Superquadro is the most

powerful twin-cylinder production engine on the planet

and is destined to power the new Ducati 1199 Panigale

with absolute performance perfection.

|

|

|