|

|

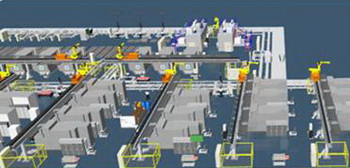

It’s been transforming how people watch

movies and TV for years. Now, Fiat and

Chrysler Group are using the world of 3D to

change the way they look at planning for

future products and implementing World Class

Manufacturing before a single machine is

built or installed. |

|

|

|

It’s

been transforming how people watch movies and TV for

years. Now, Fiat and Chrysler Group are using the world

of 3D to change the way they look at planning for future

products and implementing World Class Manufacturing

before a single machine is built or installed.

During a speech at the Management Briefing Seminars in

Traverse City, Mich., on Monday (Aug. 6), Chrysler

Group’s Brian Harlow, Vice President, Head of NAFTA

Powertrain Operations and Global Powertrain

Manufacturing Engineering, said that the company has

brought 3D into its upfront processes in order to

prepare for the launch of two important new

transmissions in Kokomo, Ind., – the eight-speed

rear-wheel drive and nine-speed front-wheel drive – as

well as other new powertrain programs.

“We knew we needed a new way of working in order to get

our plants in Kokomo ready at an accelerated pace,” said

Harlow. “By using 3D technology, we are in effect

injecting the principles of WCM from the very beginning

of our planning for production startups such as the ones

in Kokomo.”

WCM is a rigorous, integrated system that encompasses

all plant processes. The goal of WCM is to continuously

improve performance in order to reach the objective of

zero waste, which includes zero accidents, zero

breakdowns, zero waste of motion and zero inventories.

With the help of Auburn Hills, Michigan-based Strategic

Manufacturing Solutions (SMS), Chrysler Group is

utilising a three-dimensional modelling system

specifically for powertrain manufacturing to help

everyone see the shop floor as it really is and not how

one might imagine it is.

“We live in three dimensions, not two, so with a two

dimensional drawing, you had to imagine the third

dimension,” said Harlow. “Engineers have good

imaginations, but those imaginations don’t all work the

same way. If you have 10 engineers looking at a 2D

drawing, they will all see it a little differently.”

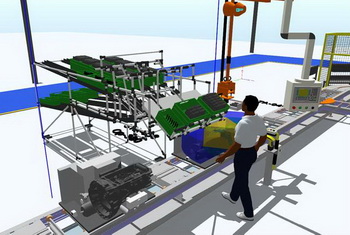

By turning the view, Harlow said that engineers can see

the manufacturing environment, including equipment,

materials and operators, as it really is. In this way,

issues that may delay a program or cost money to fix are

addressed even before the first piece of equipment

arrives at the plant.

“Three-dimensional modelling allows us to make our

actual investments as late as possible in the launch

process,” said Harlow. “The goal is to make the launch

process as vertical as possible because this shortens

the time it takes to recover our investment.”

Three-dimensional layouts are used to help figure out

where racks and materials should be stationed to bring

parts to operators in the Golden Zone, a 60-degree

window that is ideal to present parts. They can also be

used to eliminate conditions on the line that might be

unsafe or could cause injury or strain for the operator.

The software also has the capability of showing an

exploded view of a machine. By de-contenting the

machine, an operator can see all of the nuts and bolts,

making it easier to understand how it goes together,

maintain and repair.

“Animation is another critical aspect of the 3D

programming,” said Harlow. “It allows us to validate

cycle times and to discover system-related issues even

before the machinery is made.

“If there is a situation anywhere that compromises

production, we can identify it up front in the process,

something we ordinarily wouldn’t know until the first

day of production,” continued Harlow. “Now we can be

proactive. We can change cycle times by moving content

or by making changes with the machine tool builder.”

One of the other benefits of the technology is the

immediate information exchange between the plants around

the world, machine tool builders and SMS. Using a

computerized white board, people at the plant can write

directly on layouts, then that information goes back to

SMS where people immediately integrate the changes into

a master layout. At any point in time, those layouts are

available through a remote access system to anyone

anywhere in the world.

Another example of how this software is helping Chrysler

drive waste out of the system is by making it much

easier and much faster to analyse investment costs up

front. A financial calculator takes variables such as

capital investment, capacity, operating budget,

perimeter costs and cost per unit and shows how

they affect each other. Comparisons can be made fast,

side-by-side so informed decisions can be made based on

the financial consequences. “The system that we have

developed while working with SMS allows us to move fast

by pulling the discovery process way forward where we

can address issues before they ever become a problem on

the plant floor,” said Harlow.

ItaliaspeedTV:

Example of 3D

modelling in the factory development process

|

|

|